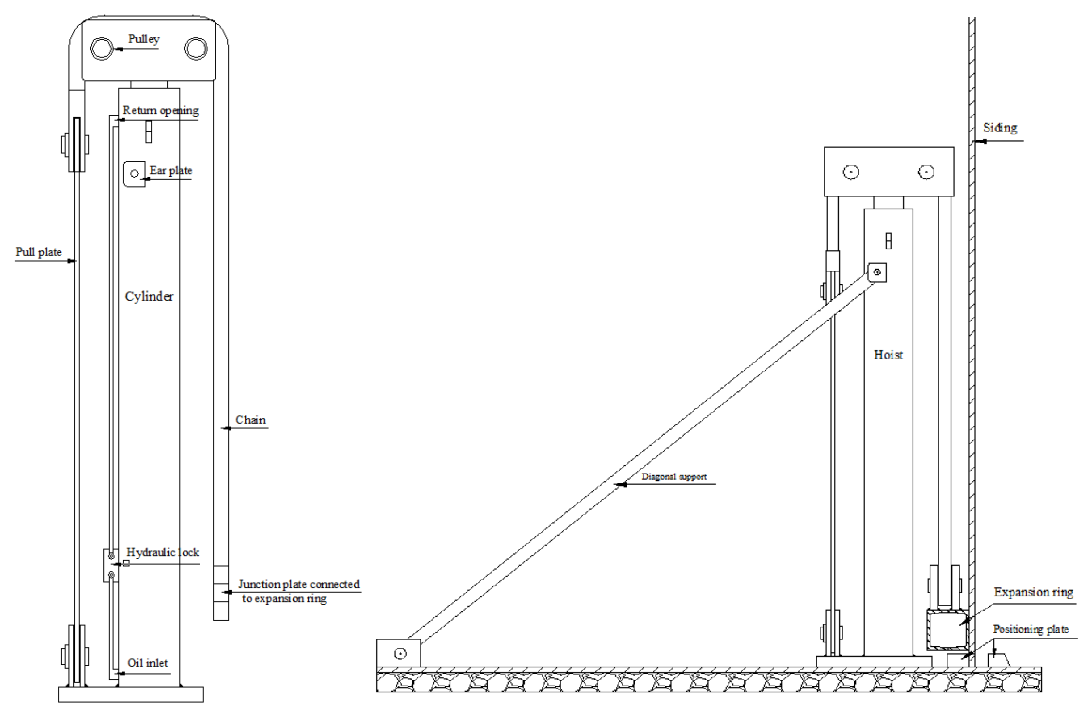

LYT-type jack is composed of one-stage double-acting hydraulic cylinder, pulley block, load-bearing chain and oil way etc. Moveable pulley is used to enlarge chain stroke, i.e. traveling distance of the cylinder is 1/2 of lifting distance of the chain. It applies to inverted installation and construction of various large storage tanks (steel) and various storage tanks.

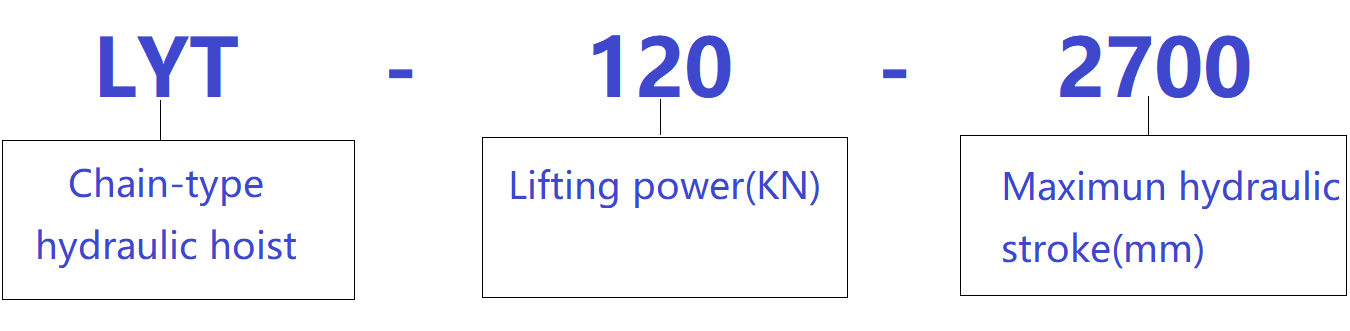

LYT-type chain-type hydraulic jack includes the following models: LYT-120-2700, LYT-200-2700, and LYT-300-2700 etc. (those with special stroke need to be customized)

Product Parameter

Product Advantages

1. Hydraulic lifting is stable, safe and reliable. Due to the adoption of unified hydraulic control and single or partial (several) adjustment, the whole lifting process is relatively stable. The hoist is provided with synchronizing valve and hydraulic lock to prevent sliding and falling of the tank or heavy loads, which are caused by power failure and fracture of oil tube. Hydraulic lifting is stable, safe and reliable.

2. Construction quality is ensured. As the hoist is provided with synchronizer and adjustable function, lifting height can be controlled accurately. Due to above reasons, quality of the tank is ensured.

3. The equipment is easy to operate. Construction environment is good and work efficiency is high.

4. The equipment is well-adapted. As long as the number of hydraulic hoists is increased or decreased, the whole set of equipment can be applied to the inverted hydraulic lifting construction of large storage tanks with different volumes ranging from several thousand cubic meters to tens of thousands cubic meters.

5. The hydraulic pump station and the hydraulic hoist are placed in the tank for easy operation. Finally, a door-closing plate is reserved to move the equipment out of the storage tank, and the door-closing plate is group welded well.

6. The hydraulic pump station can be controlled singly or jointly, and has strong construction adaptability and excellent technical performance price ratio.

7. Short construction period, low cost and good economic benefit. Due to the high degree of modernization and the fast lifting speed of the complete set of equipment, it has low construction cost and good economic benefit. This technology is truly characterized with convenient and centralized control, simple operation, safety and reliability (no falling), accurate control of weld clearance and lifting height of heavy objects, which can ensure the quality of the project, save labor and reduce costs, and achieve remarkable economic benefits.

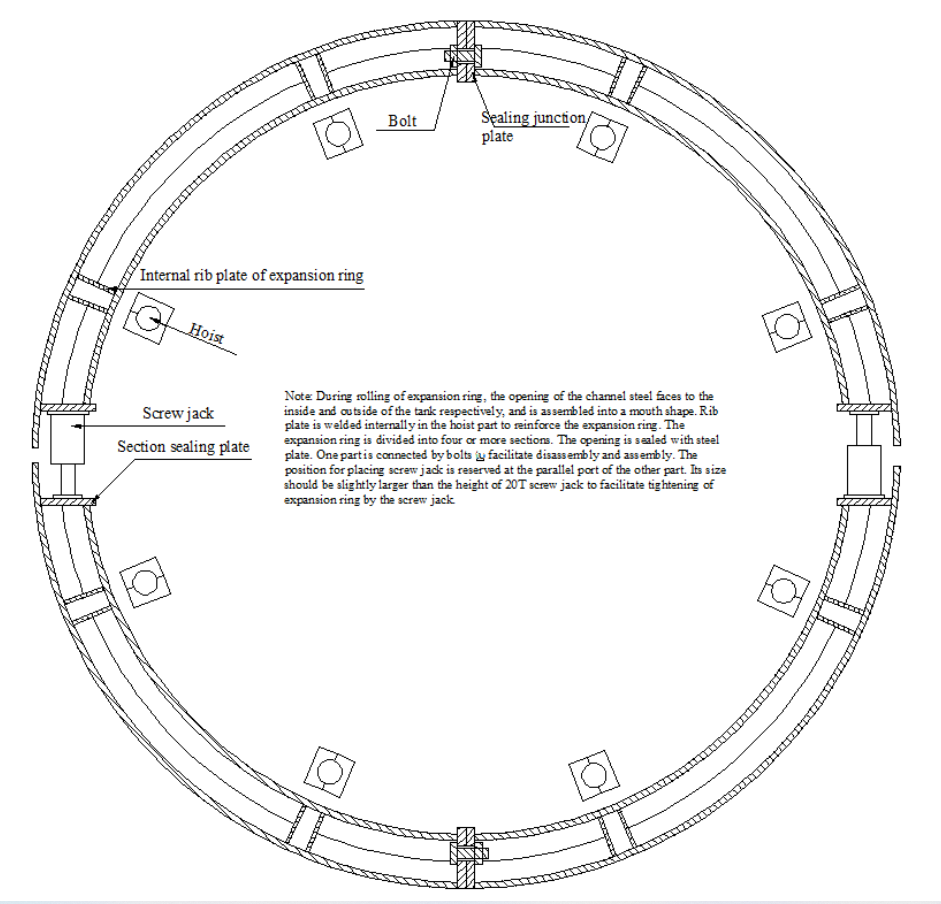

Major Component

On Site Photos