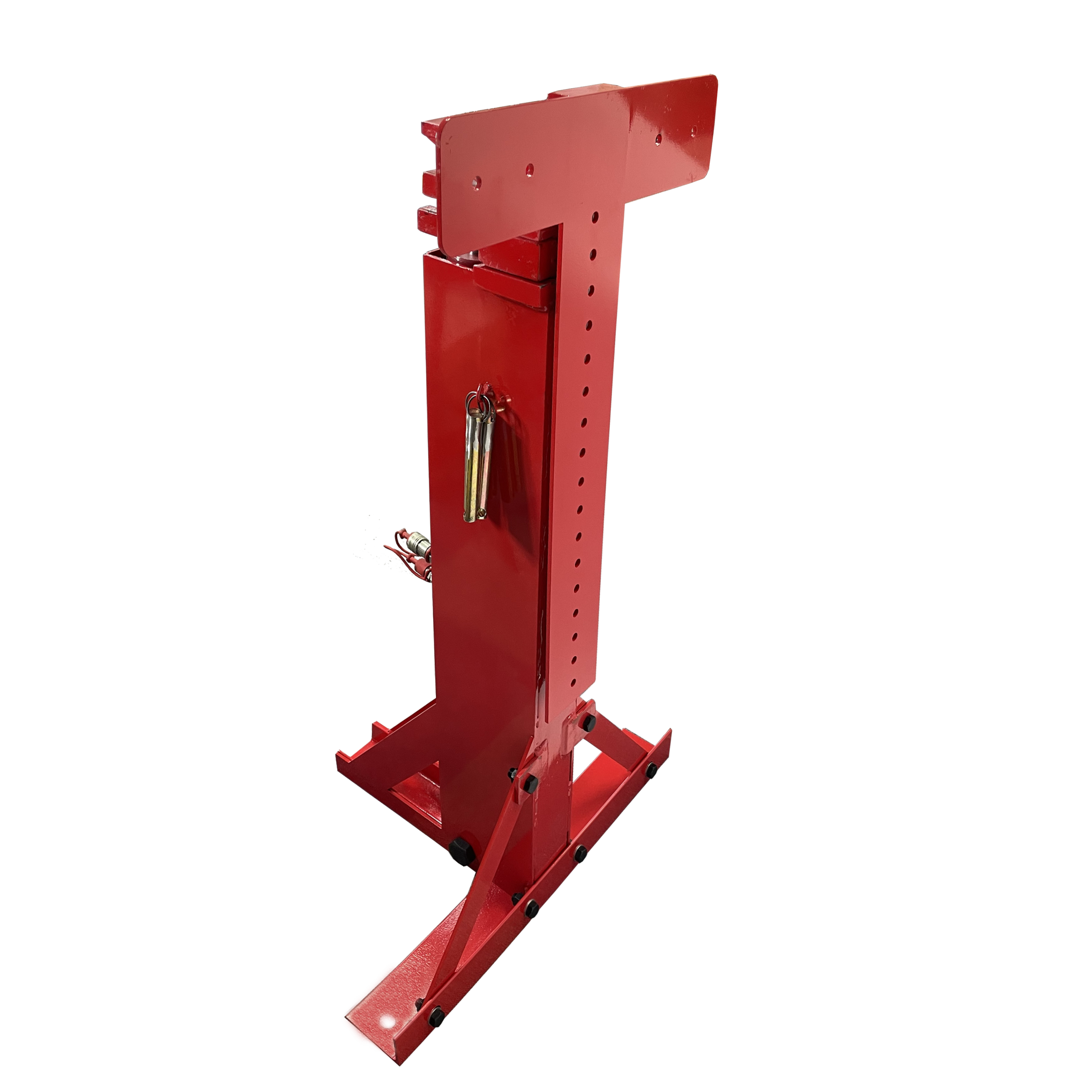

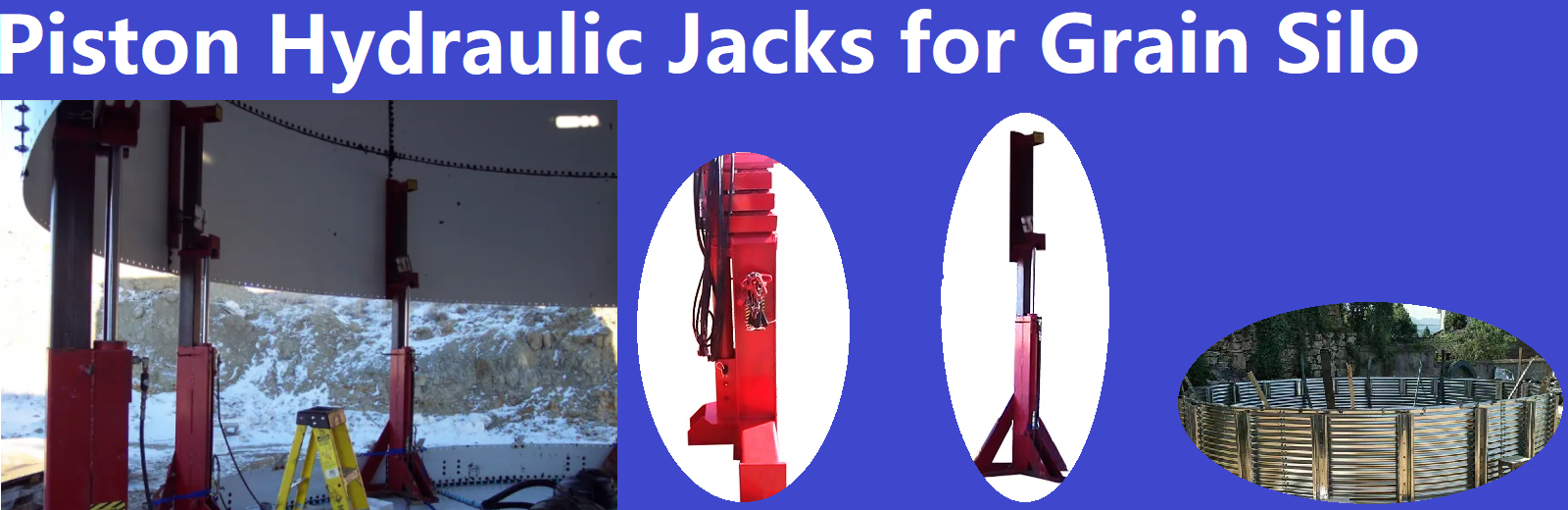

The three-stage bolted type hydraulic jacks is specially developed by our company for the inverted installation and construction of flat bottom corrugated grain silos and enamel tanks. The hydraulic jacks is mainly composed of hydraulic jacking pump station, hydraulic cylinder, rectangular steel frame, etc. At the same time, the three-stage hydraulic jacks adopts the sleeve type process design, the shape volume is smaller, the weight is lighter, the installation and transportation are easy, and the application rate is higher.

Product Parameter

Product Advantages

1, This set of equipment is mainly composed of hydraulic jacking pump station, hydraulic cylinder, rectangular steel frame, etc.,easy to install.

2, The equipment adopts PLC program to control jacking, which has the advantages of simple operation, high jacking synchronization precision and stable jacking process.

3, Hydraulic jacking pump station has two modes of manual and centralized control, hydraulic cylinder can be single or local (several) to adjust (fine tune) lift and fall; Multiple groups can be centrally controlled up and down; The jacking height can precisely control the butt adjustment of the tank wall welds.

4, Each hydraulic cylinder has a safety valve self-locking, equipment operation will not cause the tank or heavy objects to slide or fall due to power failure, the blasting of a high-pressure hose or the failure of a hydraulic cylinder, hydraulic jacking process is safe and reliable.

5, The plunger type hydraulic jacking system has no side force in the jacking process and has no influence on the tank wall.

6, The stroke of the hydraulic cylinder is 800 mm, which can meet the one-time jacking completion of the width of the wall panel below 2300 mm, reducing the jacking time, Save labor and other auxiliary costs.

7, The overall base length of the equipment is only 1180 mm, which can fully meet the inverted construction and installation process of large storage tanks, granaries and enamel tanks.

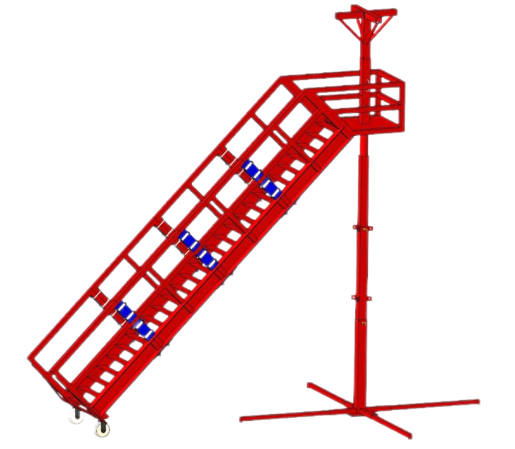

Major Component

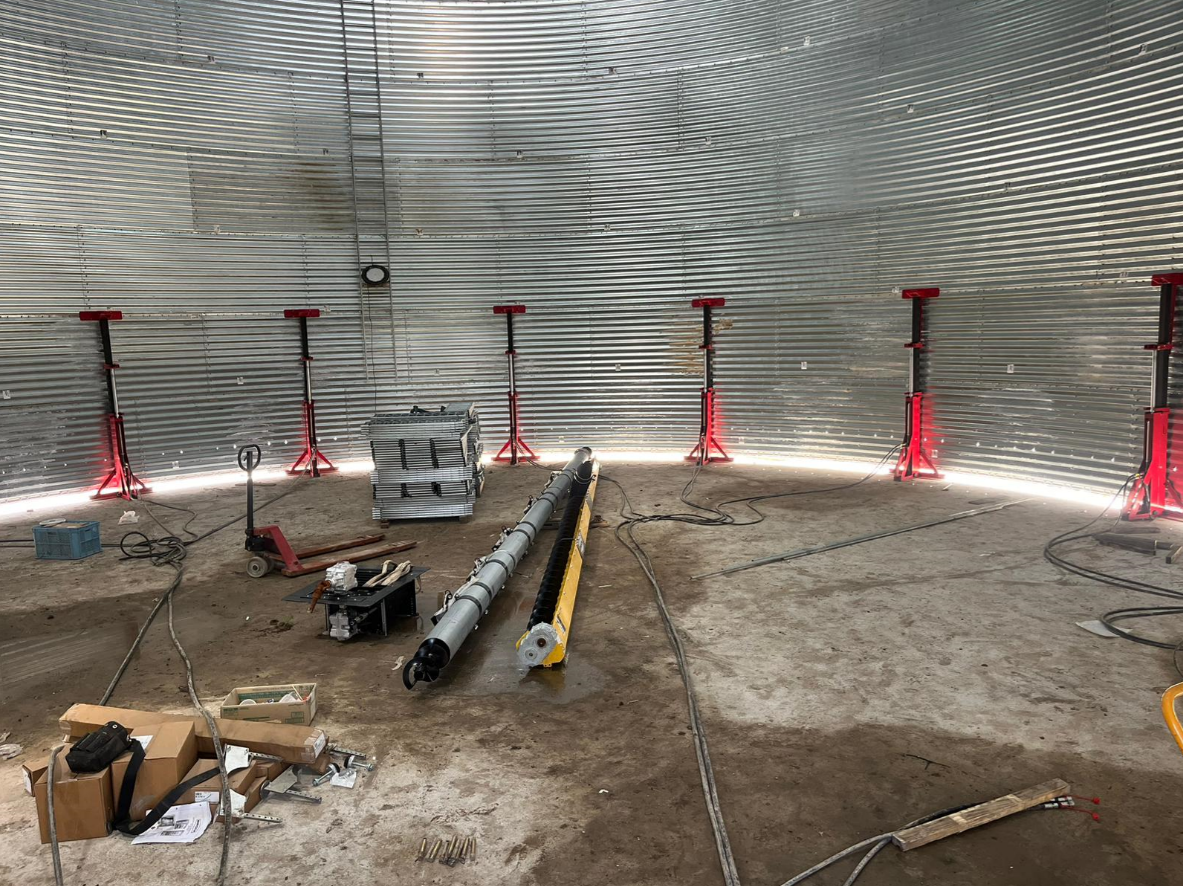

On Site Photos