Three-stage Tank Advanced Hydraulic Jacking system with PLC Control in Stock

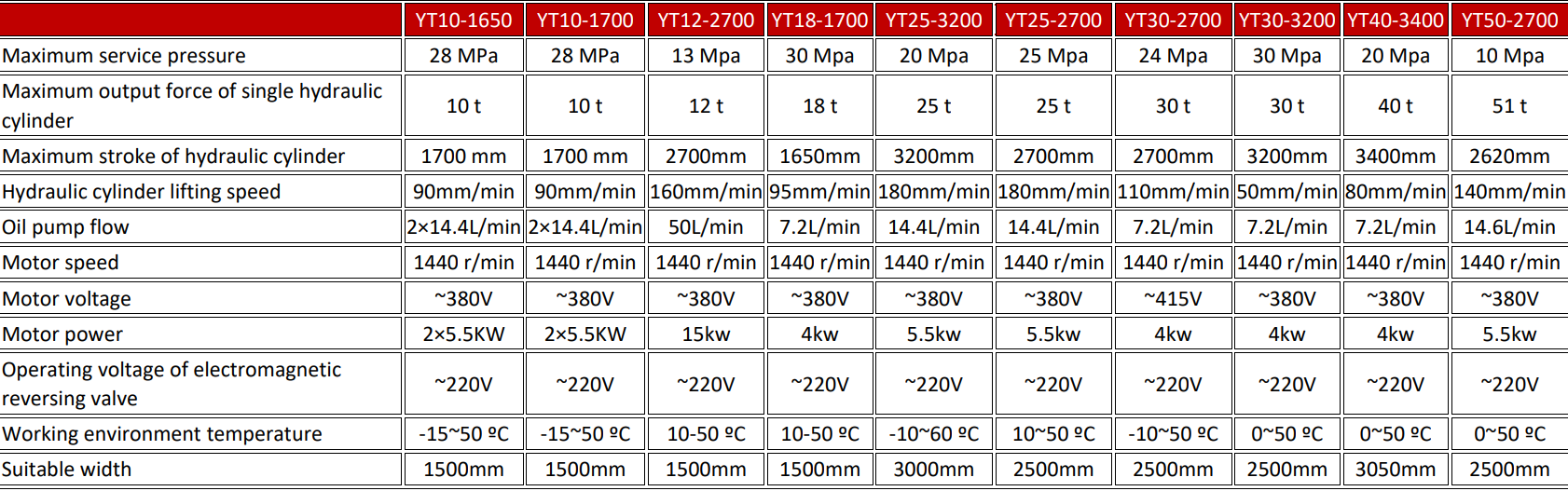

Item/Model | YT10-1650 | YT10-1700 | YT12-2700 | YT18-1700 | YT25-3200 | YT25-2700 | YT30-2700 | YT30-3200 | YT40-3400 | YT50-2700 |

Maximum service pressure | 28 MPa | 28 MPa | 13Mpa | 30Mpa | 20Mpa | 25Mpa | 24Mpa | 30Mpa | 20Mpa | 10Mpa |

Maximum output force | 10 t | 10 t | 12 t | 18 t | 25 t | 25 t | 30 t | 30 t | 40 t | 51 t |

Maximum stroke | 1700 mm | 1700 mm | 2700 mm | 1650 mm | 3200 mm | 2700 mm | 2700 mm | 3200 mm | 3400 mm | 2620 mm |

Three stage PLC control hydraulic jacking system is mainly used for inverted construction of vertical cylindrical steel storage tank (hydraulic jacking method) and inverted construction of vertical cylindrical low-temperature storage tank in petrochemical industry.It can also be used for vertical lifting and lifting of super large objects.

Product Parameter

Product Advantages

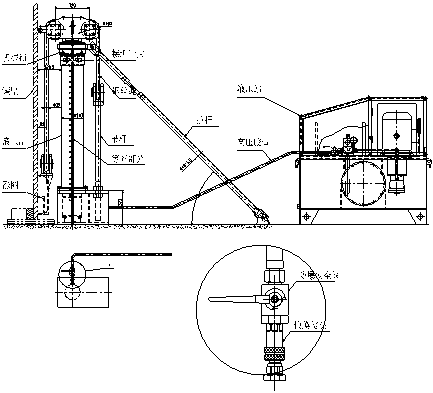

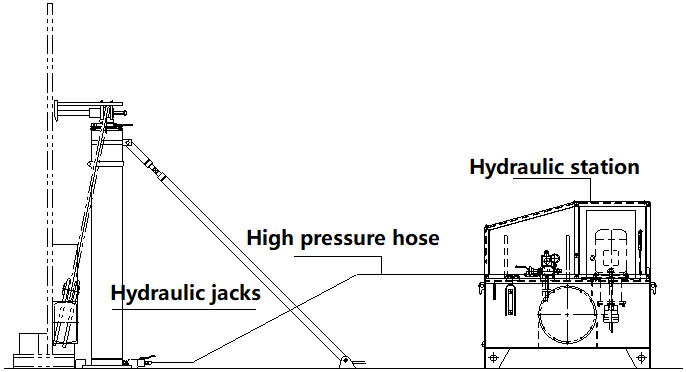

1, This set of equipment is mainly composed of a hydraulic lift station, hydraulic cylinders, steel wire ropes, etc., and is easy to install. 2, The equipment adopts PLC program centralized control for lifting. Each group of lifting pump stations is equipped with displacement sensor devices, which are easy to operate and have high lifting synchronization accuracy. The equalization distance can be adjusted arbitrarily 3, The hydraulic lift station offers two mode options: manual operation and centralized control. The hydraulic cylinders can be adjusted (fine-tuned) for lifting and lowering either individually or locally (several), and multiple groups can be centrally controlled for lifting and lowering. The lifting height can be precisely controlled, facilitating the adjustment of the weld seams on the tank wall. 4, Each hydraulic cylinder is equipped with a safety valve, which has good self-locking performance and will not be affected by power outages during the operation of the equipment. The blasting and smashing of a certain high-pressure rubber hose; The failure of a certain hydraulic cylinder causes the tank or heavy object to slide or fall, and the hydraulic lifting process is safe and reliable. 5, The hydraulic cylinder stroke is 3200 mm, which can meet the one-time lifting completion of the existing wall panel width, reducing the lifting time. 6, The overall base length of the equipment is only 2200 mm, which can fully meet the automatic welding process of the inner ring seam of large storage tanks.

Major Component

On Site Photos