Two-stage Tank Hydraulic Jacks with PLC Control Synchronous Lifting System

Model/Parameter | Max service pressure | Max output force of single hydraulic cylinder | Max stroke of hydraulic cylinder |

YT10-2200C | 24Mpa | 10T | 1250mm |

YT10-2700C | 31Mpa | 10T | 1400mm |

YT12-2700C | 31Mpa | 12T | 1400mm |

YT18-1700C | 24Mpa | 18T | 1240mm |

YT18-2000C | 24Mpa | 10T | 1240mm |

YT18-3000C | 25Mpa | 18T | 1600mm |

YT25-2700C | 31.5Mpa | 25T | 1650mm |

YT25-3000C | 29Mpa | 25T | 3200mm |

YT30-2700C | 29Mpa | 30T | 2050mm |

YT-C type hydraulic storage tank lifting equipment is a set of large hydraulic lifting equipment specially developed by our company for national crude oil reserve project in 1994.As long as the number of hydraulic cylinder and pump station system is increased or decreased, this type of equipment can be applied to the inverted construction of large storage tanks with different volumes ranging from thousands of cubic meters to hundreds of thousands of cubic meters.

Product Parameter

Model/Parameter | Max service pressure | Max output force of single hydraulic cylinder | Max stroke of hydraulic cylinder | Hydraulic cylinder lifting speed | Oil pump flow | Motor speed | Motor voltage | Motor power | Working environment temperature |

YT10-2200C | 24Mpa | 10T | 1250mm | 190mm/min | 14.4L/min | 1440r/min | ~380V | 5.5kw | -15~50 ℃ |

YT10-2700C | 31Mpa | 10T | 1400mm | 270mm/min | 7.2L/min | 1440r/min | ~380V | 5.5kw | -15~50 ℃ |

YT12-2700C | 31Mpa | 12T | 1400mm | 250mm/min | 7.2L/min | 1440r/min | ~380V | 5.5kw | -15~50 ℃ |

YT18-1700C | 24Mpa | 18T | 1240mm | 175mm/min | 7.2L/min | 1440r/min | ~380V | 4kw | 0~50℃ |

YT18-2000C | 24Mpa | 10T | 1240mm | 175mm/min | 7.2L/min | 1440r/min | ~380V | 4kw | 0~50℃ |

YT18-3000C | 25Mpa | 18T | 1600mm | 187mm/min | 7.2L/min | 1440r/min | ~380V | 5.5kw | -10~60℃ |

YT25-2700C | 31.5Mpa | 25T | 1650mm | 175mm/min | 7.2L/min | 1440r/min | ~380V | 5.5kw | -10~60℃ |

YT25-3000C | 29Mpa | 25T | 3200mm | 160mm/min | 7.2L/min | 1440r/min | ~380V | 4kw | -10~60℃ |

YT30-2700C | 29Mpa | 30T | 2050mm | 130mm/min | 7.2L/min | 1440r/min | ~415V | 4kw | -10~60℃ |

Product Advantages

1, The system consists of hydraulic pump station, cylinders, steel wire, and strokes. Easy to installation and operation;

2, The system utilizes PLC central control to handle lift. Each power pack is equipped with auxiliary balance device to guarantee the precision of simultaneously lifting;

3, Hydraulic lift pump station has subsidiary manual control and central control two operation models. The cylinder can be adjusted to lift separately or to lift with several others as one group, and multi groups can also be integrated to lift reach better precision and better welding effect;

4, All the cylinders are with safety valve. It can be automatically locked to avoid cylinder/ tank dropping even under situation of power off, high-pressure hose broken, burst;

5, The cylinder is with one high pressure hose to avoid oil leaking that usually happen by the traditional multiple hoses. Cylinder will return to initial condition by itself weight;

6, Stroke of Hydraulic cylinder is various as per tank plate width, which can satisfy each annular shell plate one-step lift. Greatly reduce the time waste;

7, Hydraulic cylinder basic height is based on the tank shell width, which can match automatic girth welding machine to proceed internal girth seam welding;

8, Module configuration, the jacking system quantity can be adjusted as per different size of tank and weight;

9, High efficiency, each time lifting or falling down only needs around 15 minutes;

10, Can well cooperate with our tank welding machines, which can greatly reduce the manpower cost and reduce the construction time.

Major Component

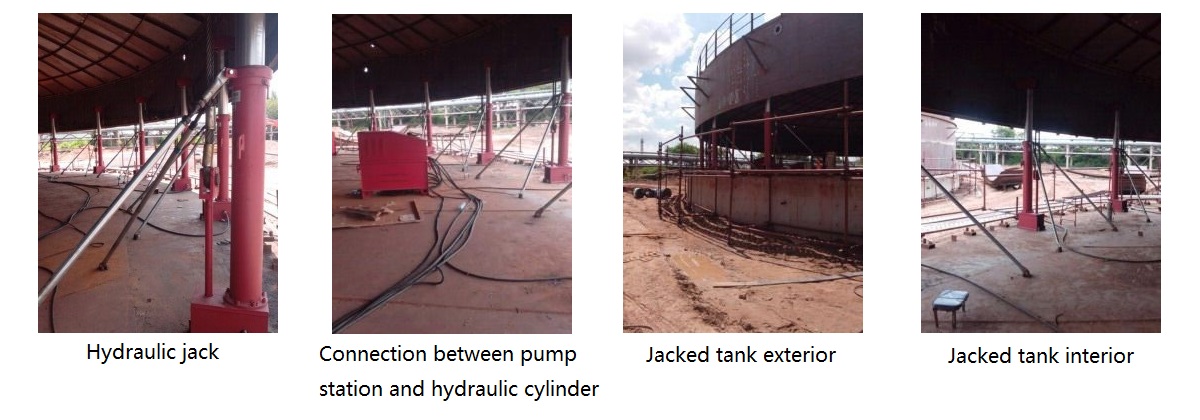

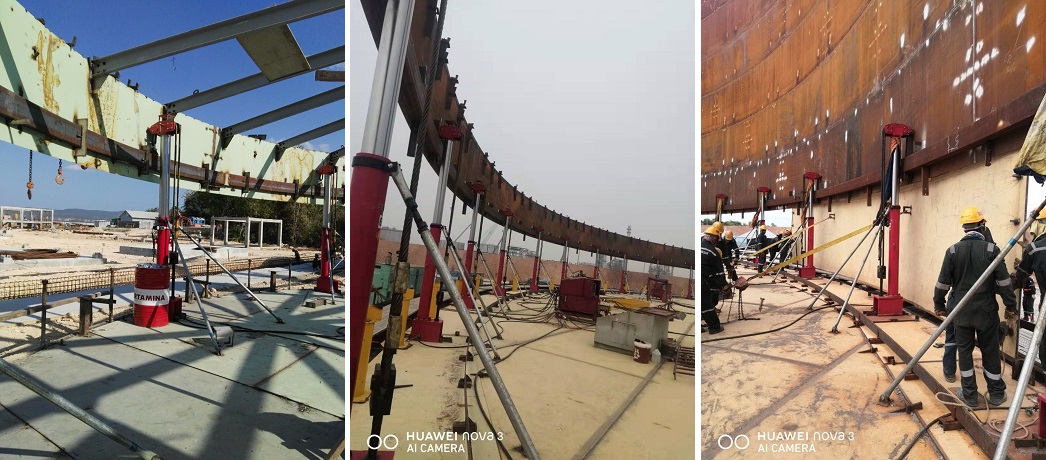

On Site Photos