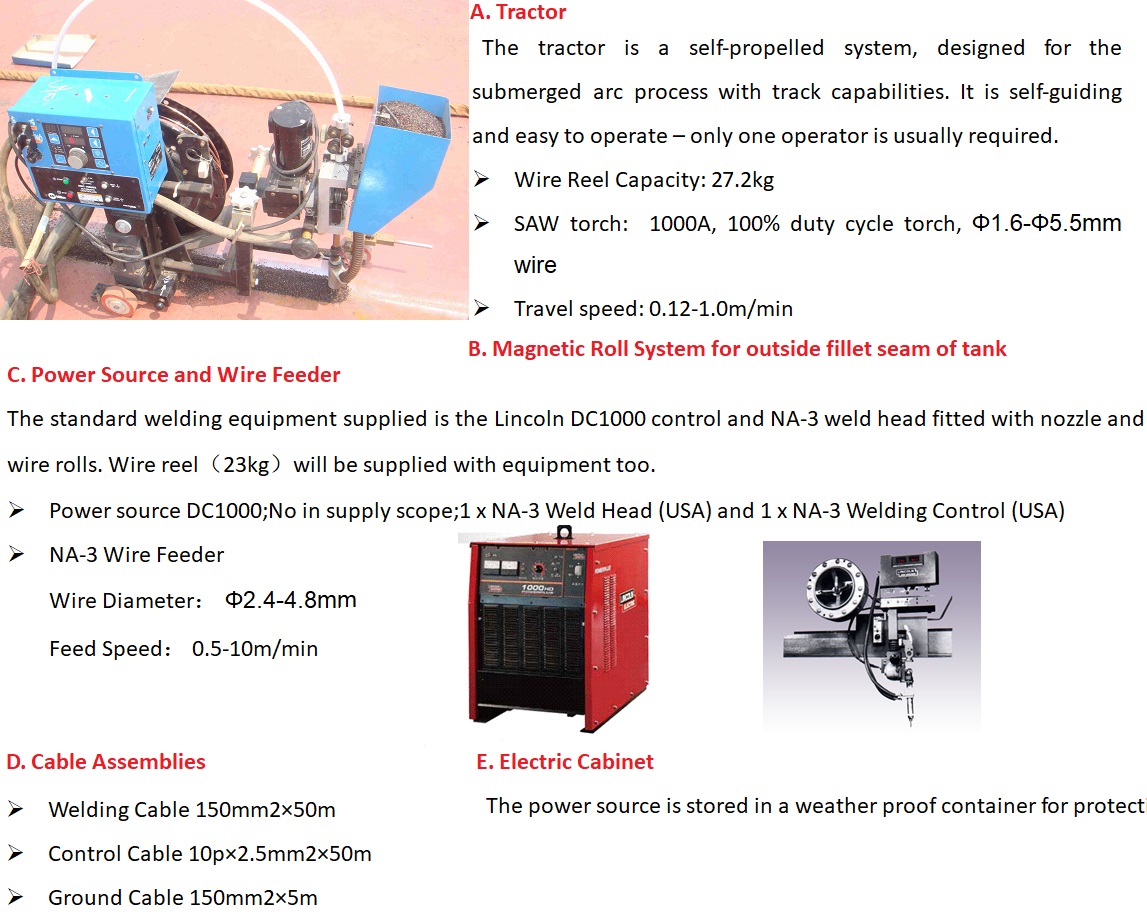

The automatic butt and corner welding machine is a dual-purpose equipment for both flat and fillet welds. When welding flat joints or lap joints, the welding machine moves on the guide rail for welding. When welding the inner and outer fillet welds of the vertical cylinder, due to the adoption of a special magnetic adsorption device, automatic welding can be achieved without the use of tracks. When welding the outer corner seams of stainless steel storage tanks, users can make auxiliary tools or guide rails on site according to the diameter of the storage tanks. The entire system has good self-guiding properties and operates smoothly, ensuring that the welding torch is always aimed at the weld seam.

Product Parameter

Product Advantages

It is applicable to the welding of butt joints, lap joints and inner and outer joints of storage tanks, as well as the annular corner joints of water tank bottom plates, etc. It can achieve automatic welding of different types of welds such as butt flat welds, lap fillet welds, and T-shaped fillet welds. It has excellent characteristics such as high working efficiency, stable working performance, good welding quality and good working conditions.

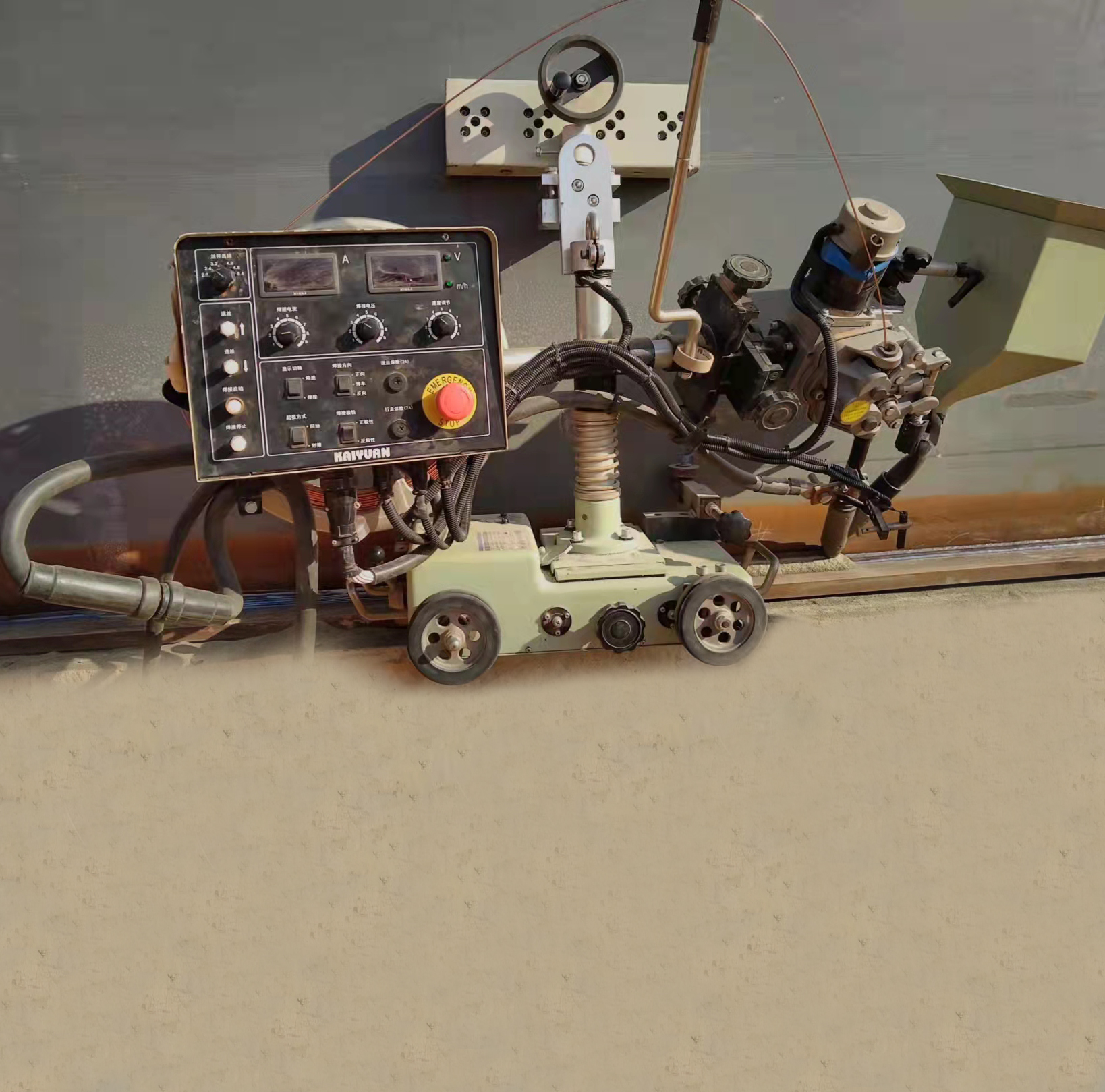

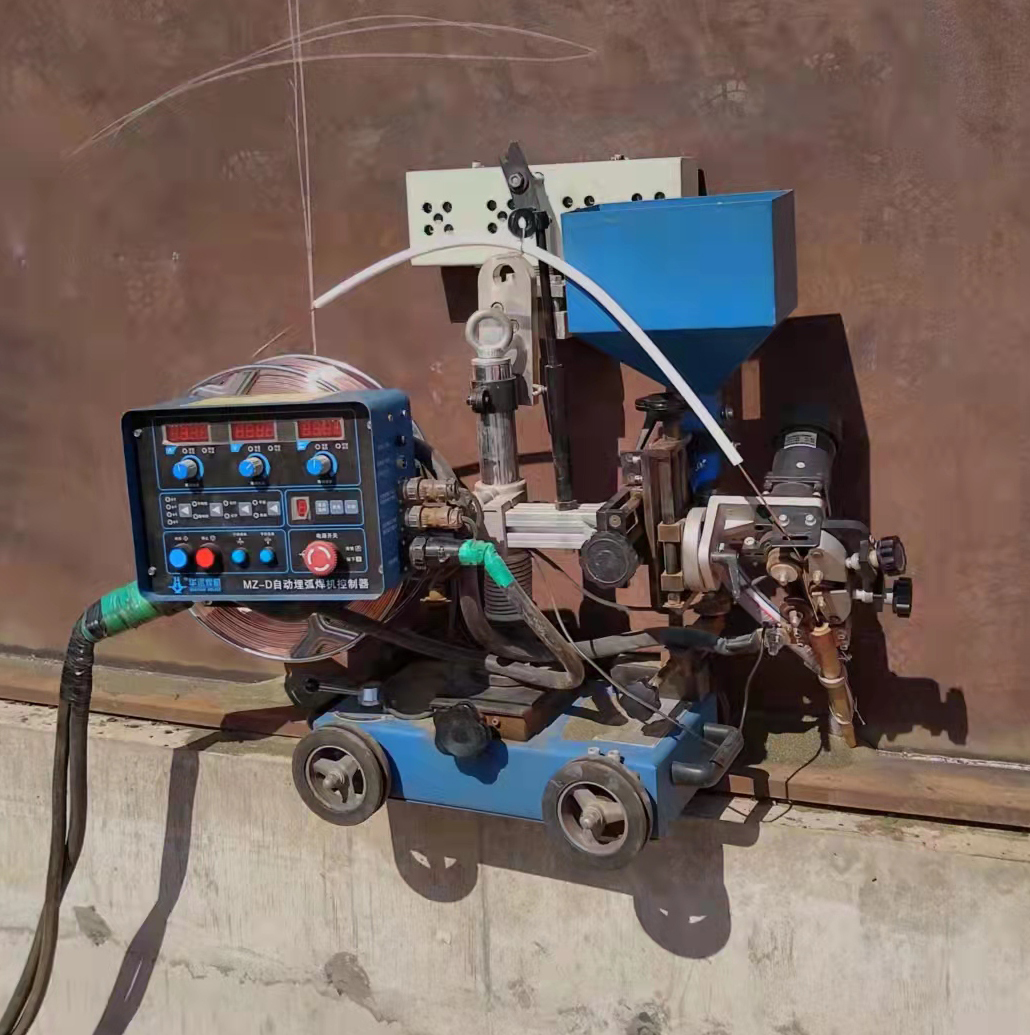

Major Component

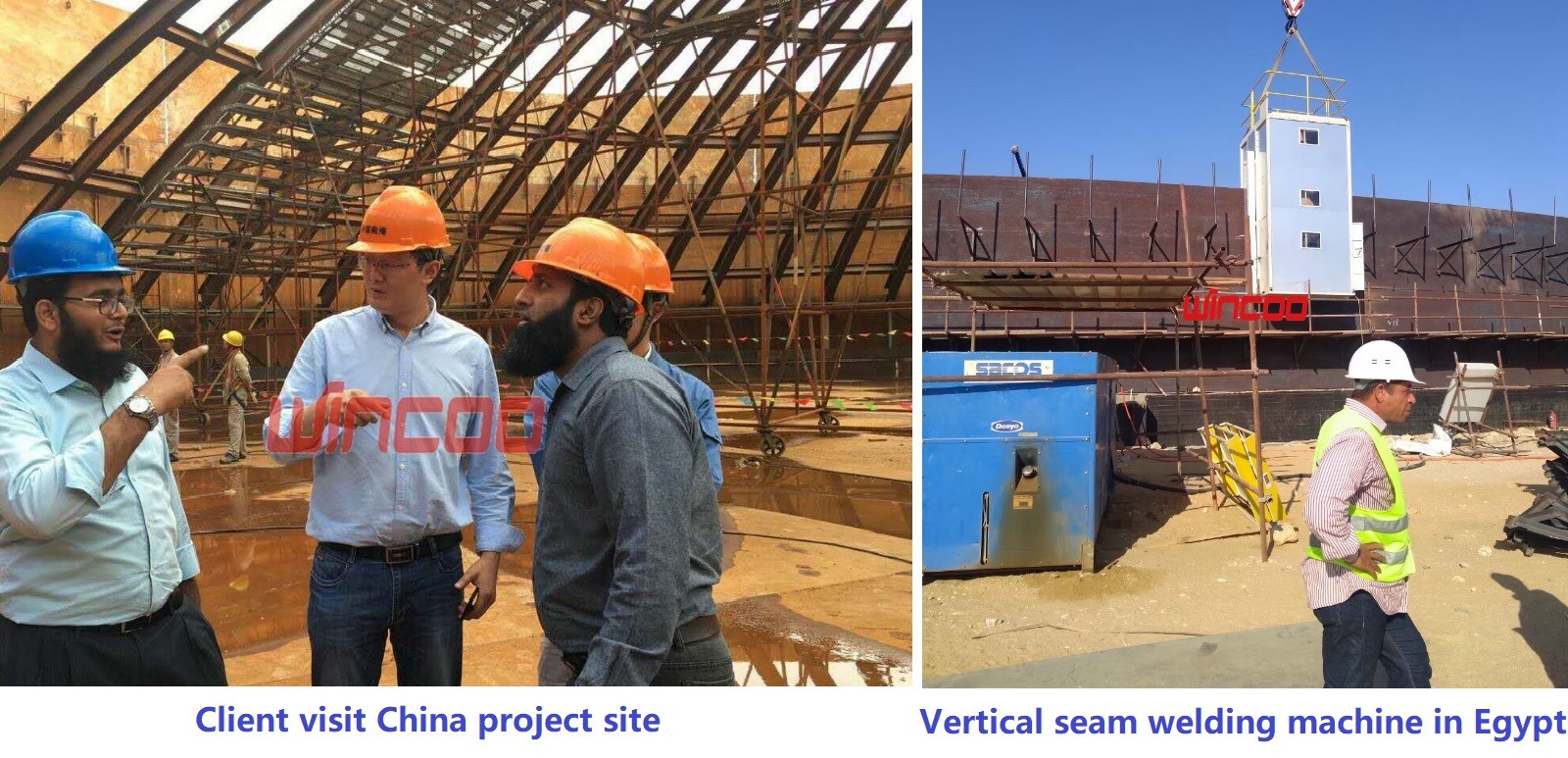

On Site Photos